Introduction

Pyrex (trademarked as PYREX and pyrex) is a brand introduced by Corning Inc. in 1915, initially for a line of clear, low-thermal-expansion borosilicate glass used for laboratory glassware and kitchenware. It was later expanded in the 1930s to include kitchenware products made of soda–lime glass and other materials.[1] Its name has become famous for making rectangular glass roasters.

In 1998, the kitchenware division of Corning Inc. responsible for the development of Pyrex spun off from its parent company as Corning Consumer Products Company, subsequently renamed Corelle Brands. Corning Inc. no longer manufactures or markets consumer products, only industrial ones.

1. PYREX® Serialized/Certified Volumetric Glassware

1. Now tested and calibrated in an ISO/IEC 17025 certified laboratory

The accuracy of volumetric glassware can have a significant impact on experimental and testing results. This is why quality glassware is made in compliance with ASTM or industry recognized standards. In fact, PYREX glassware has long been, and will continue to be, made to ASTM standards.

But now, we’ve taken our glassware quality control to an even higher level. As an added assurance of accuracy and precision, PYREX volumetric glassware is now tested and calibrated in an ISO/IEC 17025 accredited laboratory.

2. The Measure of Glassware Accuracy

To be ISO/IEC 17025 certified, an accredited laboratory must demonstrate high levels of competency for testing and calibration. ISO/IEC 17025 accreditation is your assurance that our laboratory has the appropriate quality management systems and technical competence to accurately and precisely test and calibrate your glassware.

3. Another Milestone in a 100-year Legacy

ISO/IEC 17025 accreditation is the latest chapter in the PYREX story of continuous improvement and innovation. Invented by Corning in 1915, PYREX’s chemically stable, heat-resistant, low-expansion borosilicate formula has been at the heart of groundbreaking discoveries and advancements in medicine, chemistry, and countless other fields. For more information, visit www.corning.com/pyrex.

4. Available for a Variety of Glassware

- Volumetric PYREX glassware tested and calibrated in accordance with ISO/IEC 17025 includes:

- ◗ Burets

- ◗ Volumetric flasks

- ◗ Volumetric and measuring pipets

- ◗ Graduated cylinders

2. History

Borosilicate glass was first made by German chemist and glass technologist Otto Schott, founder of Schott AG in 1893, 22 years before Corning produced the Pyrex brand. Schott AG sells the product under the name “Duran”.

In 1908, Eugene Sullivan, director of research at Corning Glass Works, developed Nonex, a borosilicate low-expansion glass, to reduce breakage in shock-resistant lantern globes and battery jars. Sullivan had learned about Schott’s borosilicate glass as a doctoral student in Leipzig, Germany. Jesse Littleton of Corning discovered the cooking potential of borosilicate glass by giving his wife Bessie Littleton a casserole dish made from a cut-down Nonex battery jar. Corning removed the lead from Nonex and developed it as a consumer product.[2] Pyrex made its public debut in 1915 during World War I, positioned as an American-produced alternative to Duran.

A Corning executive gave the following account of the etymology of the name “Pyrex”:

The word PYREX is probably a purely arbitrary word which was devised in 1915 as a trade-mark for products manufactured and sold by Corning Glass Works. While some people have thought that it was made up from the Greek [[[wikt:πῦρ|pyr]]] Error: {{Transliteration}}: transliteration text not Latin script (pos 8) (help) and the Latin rex, we have always taken the position that no graduate of Harvard would be guilty of such a classical hybrid.

Actually, we had a number of prior trade-marks ending in the letters ex. One of the first commercial products to be sold under the new mark was a pie plate, and in the interests of euphonism the letter r was inserted between pie and ex and the whole thing condensed to PYREX.[3]

Corning purchased the Macbeth-Evans Glass Company in 1936 and their Charleroi, PA plant was used to produce Pyrex opal ware bowls and bakeware made of tempered soda–lime glass.[4] In 1958 an internal design department was started by John B.

Ward. He redesigned the Pyrex ovenware and Flameware. Over the years, designers such as Penny Sparke, Betty Baugh, Smart Design, TEAMS Design, and others have contributed to the design of the line.

3. Trademark

In Europe, Africa, and the Middle East, a variation of the PYREX (all uppercase) trademark is licensed by International Cookware[20] for bakeware that has been made of numerous materials including borosilicate and soda–lime glass, stoneware, metal, plus vitroceramic cookware.[21]

The pyrex (all lowercase, introduced in 1975[22]) trademark is now used for kitchenware sold in the United States, South America, and Asia.[23] In the past, the brand name has also been used for kitchen utensils and bakeware by other companies in regions such as Japan and Australia.

It is a common misconception that the logo style alone indicates the type of glass used to manufacture the bakeware.[24] Additionally,

Corning’s introduction of soda-lime-glass-based Pyrex in the 1940s predates the introduction of the all lowercase logo by nearly 30 years.[25][22][26]

4. Composition

Older clear-glass Pyrex manufactured by Corning, Arc International’s Pyrex products, and Pyrex laboratory glassware are made of borosilicate glass. According to the National Institute of Standards and Technology, borosilicate Pyrex is composed of (as percentage of weight): 4.0% boron, 54.0% oxygen, 2.8% sodium, 1.1% aluminum, 37.7% silicon, and 0.3% potassium.[27][28]

According to glass supplier Pulles and Hannique, borosilicate Pyrex is made of Corning 7740 glass and is equivalent in formulation to Schott Glass 8330 glass sold under the “Duran” brand name.[29] The composition of both Corning 7740 and Schott 8330 is given as 80.6% SiO2, 12.6% B2O3, 4.2% Na2O, 2.2% Al2O3, 0.1% CaO, 0.1% Cl, 0.05% MgO, and 0.04% Fe2O3.

In the late 1930s and 1940s, Corning also introduced new product lines under the Pyrex brand using different types of glass. Opaque tempered soda–lime glass was used to create decorated opal ware bowls and bakeware, and aluminosilicate glass was used for Pyrex Flameware stovetop cookware. The latter product had a bluish tint caused by the addition of alumino-sulfate.[30][31]

Beginning in the 1980s, production of clear Pyrex glass products manufactured in the USA by Corning was also shifted to tempered soda–lime glass, like their popular opal bakeware.[25] This change was justified by stating that soda–lime glass has higher mechanical strength than borosilicate—making it more resistant to physical damage when dropped, which is believed to be the most common cause of breakage in glass bakeware.

The glass is also cheaper to produce and more environmentally friendly. Its thermal shock resistance is lower than borosilicate’s, leading to potential breakage from heat stress if used contrary to recommendations. Since the closure of the soda–lime plant in England in 2007, European Pyrex has been made solely from borosilicate.[5][32][33]

- Use in telescopes

Because of its low expansion characteristics, borosilicate glass is often the material of choice for reflective optics in astronomy applications.

In 1932, George Ellery Hale approached Corning with the challenge of fabricating the 200-inch (5.1 m) telescope mirror for the California Institute of Technology’s Palomar Observatory project.[36] A previous effort to fabricate the optic from fused quartz had failed, with the cast blank having voids. The mirror was cast by Corning during 1934–1936 out of borosilicate glass.[37] After a year of cooling, during which it was almost lost to a flood, the blank was completed in 1935. The first blank now resides in the Corning Museum of Glass.[38]

6. Safety Features and Benefts of PYREX® and PYREXPLUS® Brand Labware

This section provides product information for the various types of glass labware products made by Coming. In addition, we have provided tips and additional suggestions on the safe use and care of your lab products.

1. PYREX® Labware

PYREX glass has proven itself to be tough and reliable for over 100 years of demanding use in the laboratory environment. The PYREX name is associated with high quality, corrosion- and heatresistant laboratory glassware throughout the world. Corning products are designed and produced with safety in mind. It is important to remember that most labware products are designed for specifc applications. Be sure you have the right piece of ware for the use you have in mind. Using a laboratory glassware product for applications other than those it was designed for can be dangerous.

2. Beakers

PYREX brand beakers are manufactured with uniform wall thickness, and offer an optimum balance between thermal shock resistance and mechanical strength. Large, permanent marking spots on PYREX beakers allow the user to record more data on the vessel to help identify the contents quickly and easily. Most impact breakage occurs on a beaker’s rim. PYREX brand beakers have extra glass in the rim for added strength. The pour spout is gently sloped rather than hooked, minimizing breakage. The low-fare spout allows controlled pouring

3. Centrifuge

Tubes PYREX brand centrifuge tubes are made from durable Code No. 7740 borosilicate glass with special design consideration given to stress points caused by centrifugal forces. Before centrifuging hazardous chemicals or expensive samples, consult the nomogram on page 121 for computing relative centrifugal forces (RCF) to determine safe centrifugation rates.

4. Cylinders

The most important specifcation for graduated cylinders is tolerance. Selected tubing and careful calibrations assure meeting tolerances in PYREX brand cylinders. In addition, Corning was the frst to put hexagonal bases on cylinders to keep them from rolling off a lab bench. Legibility was improved by designing Lifetime Red™ panel cylinders. Two cylinders of special safety interest are the 3046 and 3050 graduated cylinders. Both feature a reinforced bead of glass near the top of the rim. The reinforced bead helps to reduce breakage if the cylinder is upset. These cylinders are available in 10 mL, 25 mL, 50 mL, 100 mL, and 250 mL capacities.

5. Uniform Flasks

wall thickness, characteristic of all round bottom PYREX fasks, allows the vessels to satisfy various mixing, heating, and boiling requirements commonly encountered in most laboratory work. The thick walls of Corning flter fasks provide the mechanical strength needed for vacuum work. Consequently, flter fasks should never be heated. For this reason, the words “Filter Flask” appear on the product. Standard Erlenmeyer fasks are suitable for moderate heating, though they are primarily intended for mixing applications.

6. Stopcocks and Joints

1. PYREX Brand All Glass Stopcocks

General purpose PYREX brand glass stopcocks with the symbol are manufactured with 1:10 tapers and fnishes as specifed in ASTM E-675. They feature interchangeable solid glass plugs. PYREX brand glass stopcocks with hollow, blown-glass plugs are lapped to the outer shell, thus insuring uniformity between mating surfaces. They can function safely to 104 torr. (mm of Hg) of vacuum with minimal leakage.

PYREX Glass-bodied Stopcocks with PTFE Plugs

These general purpose stopcocks are marked with the symbol and manufactured with 1:5 tapers and fnishes as specifed by ASTM. Because no lubricant is needed, they are ideal for applications where grease contamination is a factor.

2. Rotafo® Stopcocks

The Rotafo stopcock can be used under varying conditions, ranging from general purpose to high vacuum applications. These stopcocks are ideal for applications where contamination is a factor; only PTFE and borosilicate glass come in contact with liquids or gases. The Hi-Vac Rotafo stopcock is designed to function safely to 103 torr. (mm of Hg) of vacuum with minimal leakage. They can be used at temperatures ranging from -20°C to 200°C and autoclaved at 20 psi and 126°C.

3. Joining and Separating Glass Apparatus

When pieces are not to be used for an extended period of time, take apart stopcocks, ground joints, fask stoppers, and joints to prevent sticking. Remove the grease from the joints. PTFE stoppers and stopcocks should be loosened slightly. For easy storage and reuse, put a strip of thin paper between ground joint surfaces.

4. Freeing Seized Ground Joints

If a ground joint sticks, this procedure will generally free it. Immerse the joint in a glass container of freshly poured carbonated liquid. You will be able to see the liquid penetrate between the ground surfaces. When the surfaces are wet (allow 5 to 10 minutes submersion), remove the joint and rinse with tap water. Wipe away excess water.

5. Lubricating Stopcocks and Stoppers

Glass stopcocks on burets and separatory funnels should be lubricated frequently to prevent sticking. If one does stick, a stopcock plug remover, available from laboratory supply houses, should be used. Wet both tubing and stopper with glycerin or water when trying to insert glass tubing into a rubber stopper. Wear a protective glove and wrap glass in a towel to prevent injury. Fire polish rough ends of glass tubing before inserting into fexible tubing or through a stopper. If it becomes impossible to remove a thermometer from a rubber stopper, it is best to cut away the stopper rather than to risk breaking the thermometer. In using lubricants, it is advisable to apply a light coat of grease completely around the upper part of the joint. Use only a small amount and avoid greasing that part of the joint that contacts the inner part of the apparatus.

6. Types of Lubricants

Three types of lubricant are commonly used on standard taper joints. (a) A hydrocarbon grease is the most widely used. It can be easily removed by most laboratory solvents, including acetone. (b) Because hydrocarbon grease is so easily removable, silicone grease is often preferred for higher temperature or high vacuum applications. It can be removed readily with chlorinated solvents. (c) For long-term refux or extraction reactions, a watersoluble, organic-insoluble grease, such as glycerin is suitable. Water will clean glycerin.

Volumetric Ware

The accuracy of volumetric ware depends on the care used in calibrating it, using the correct type of ware for the application, handling the ware properly, and insuring the ware is clean. Calibration of volumetric ware is usually done at 20°C, and the ware should be used at approximately this temperature. Refrigerated liquids should be allowed to come to room temperature before measuring them. Under normal use and care, the calibration of volumetric ware will not change. Do not expose volumetric ware to excessive heat, approaching PYREX® upper service limit.

7. Types of Ware

8. Serialized/Certifed Ware:

Certifed Ware is calibrated to Class A specifcations. Each piece is individually serialized and furnished with a Certifcate of Identifcation and Capacity, traceable to NIST standards, guaranteeing its calibration. 9. Class A Ware

Class A Ware is manufactured to tolerances established by ASTM E-694 for volumetric ware, ASTM E-542 for calibration of volumetric ware, and ASTM E-288 for volumetric fasks. Utilizes the same tolerances as certifed ware but is not certifed and has no certifcate.

9. Class B Ware

Class B Ware is generally calibrated to twice the tolerance of Class A Ware. Other Types: There are also some specifcations for other calibrated glassware, set by various federal bureaus or professional societies. Tolerances for these and references to the specifcations are found in this catalog under individual product descriptions.

10. Calibrated Ware Markings

Lines on graduated ware may be acid etched, wheel engraved, abrasive blasted, enameled, or permanently stained into the glass. Etched or engraved lines are usually colored by fred-in enamels. The width of the lines should not exceed 0.4 mm for subdivided ware or 0.6 mm for single-line ware. In addition to the lines, the ware should be marked with its capacity, the temperature at which it should be used, and whether the piece was calibrated T.C. (“to contain”) or T.D. (“to deliver”) the stated volume. T.C. means that the ware is calibrated so that the the mark indicates the volume held in the container. T.D. means the mark indicates the amount of air-free distilled water at 20°C that is delivered when it is poured out. Numbers indicating volume at certain lines are placed immediately above the line. Volumetric fask markings must cover at least 90% of the neck circumference.

Question

1. What is a burette with a stopcock used for?

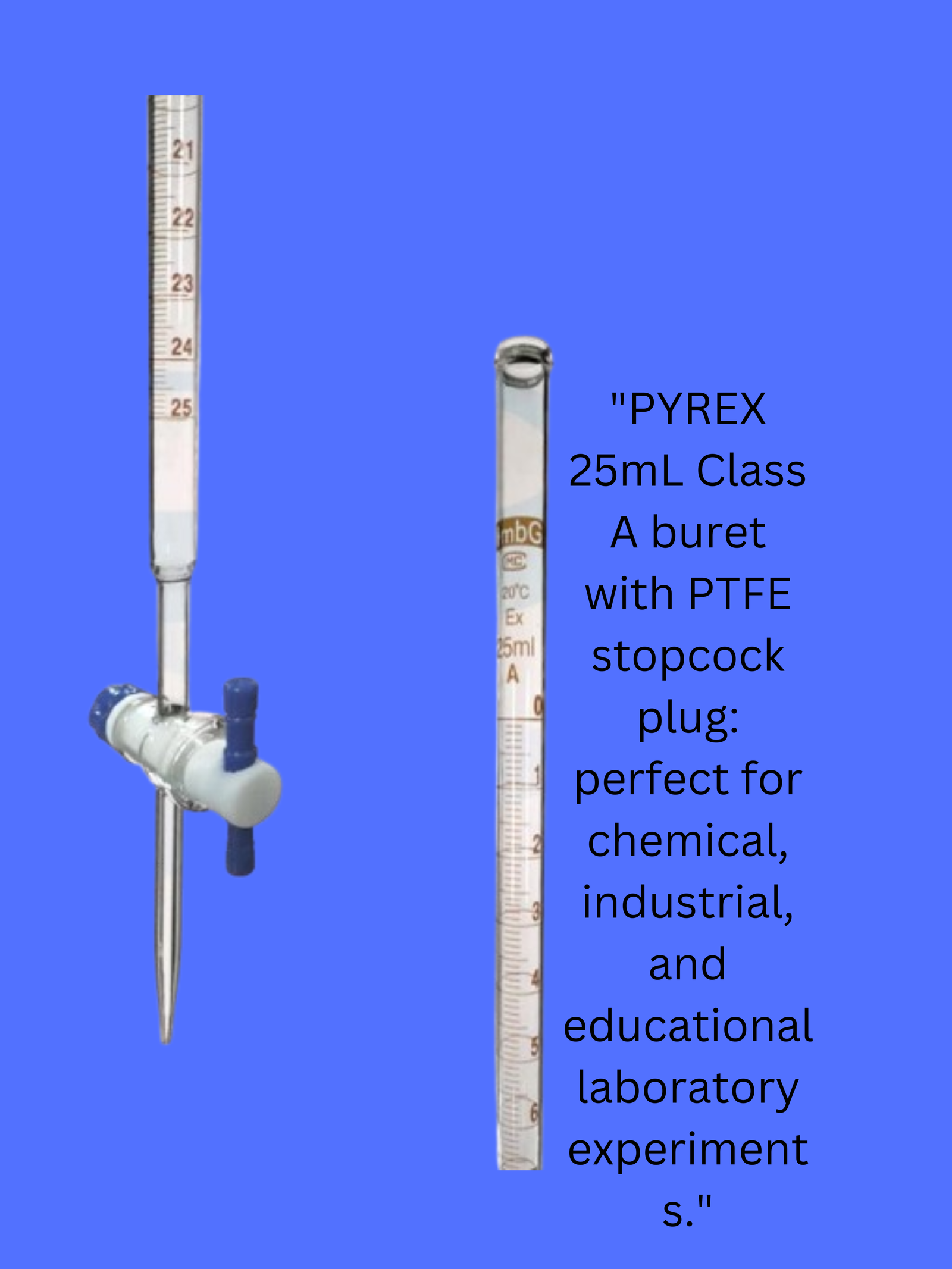

Used to dispense and measure a variable amount of a chemical solution in analytical chemistry at the same time, burettes feature a long, graduated glass tube with a stopcock on its lower end for liquid measurement.

2. What is the stopcock position of a Buret?

When adding solutions to the buret, make sure the stopcock is closed (horizontal position). Unclamp the buret and tilt it slightly while pouring the solution slowly down the inside surface. This will prevent the formation of air bubbles.

3. What is the use of burette with Teflon stopcock in laboratory?

A burette with a PTFE stopcock is a laboratory instrument used to measure and dispense precise volumes of liquids. It consists of a cylindrical glass or plastic tube with graduations (marks indicating volume) along its length and a stopcock, which is a valve that controls the flow of liquid through the burette.

4. Are there any differences in the warranty, quality level or manufacturing process compared to other PYREX® products?

A.The manufacturing process is strictly the same for all three types (Regular, Certified by Lot and Individually Cert/Serial volumetric). It is important to note that the internal Corning specs at the plant are even more rigorous 20% to 25% compared to ASTM standards. The only difference in place is the fact the individually certified/serial product is measured piece by piece and the others are checked in a rigorous sampling process.

5. Is the product made with Pyrex glass?

- PYREX© is a Corning Inc. registered brand and can only be used by Corning and its subsidiaries. It does not reflect any type of material. However the glass used in the products is indeed the same type that made PYREX brand reputation for resistance and quality for more than 100 years: low expansion borosilicate glass (< 33×10-7 cm/cm/oC) CORNING 7740, that attends to ASTM E 438 Type I, Class A.

- What is the stopcock used for?

The stopcock is a valve for turning off and on the cold water system in your home. When you turn the stopcock in a clockwise direction the water supply will be shut off. You can turn the water supply back on by turning the stopcock in an anti-clockwise direction.